Tower Mill

Product Description

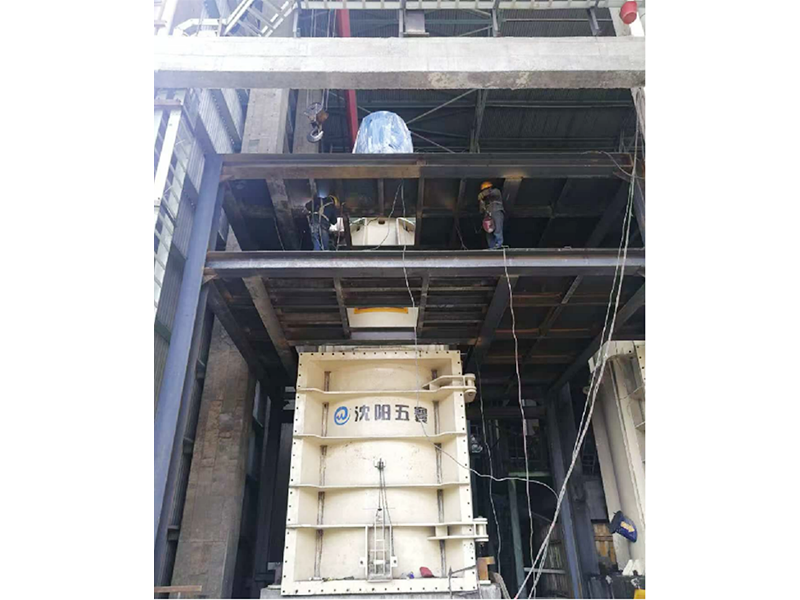

Tower Mill

The Tower Mill achieves precise control over mineral particle size with its excellent fine grinding capability, laying a solid foundation for subsequent separation. At the same time, it has energy-saving advantages, reducing production costs; it operates with low noise, creating a green production environment; its performance is stable, ensuring efficient and continuous production. It effectively enhances mineral separation efficiency and product quality.

Tower Mill Technical characteristics

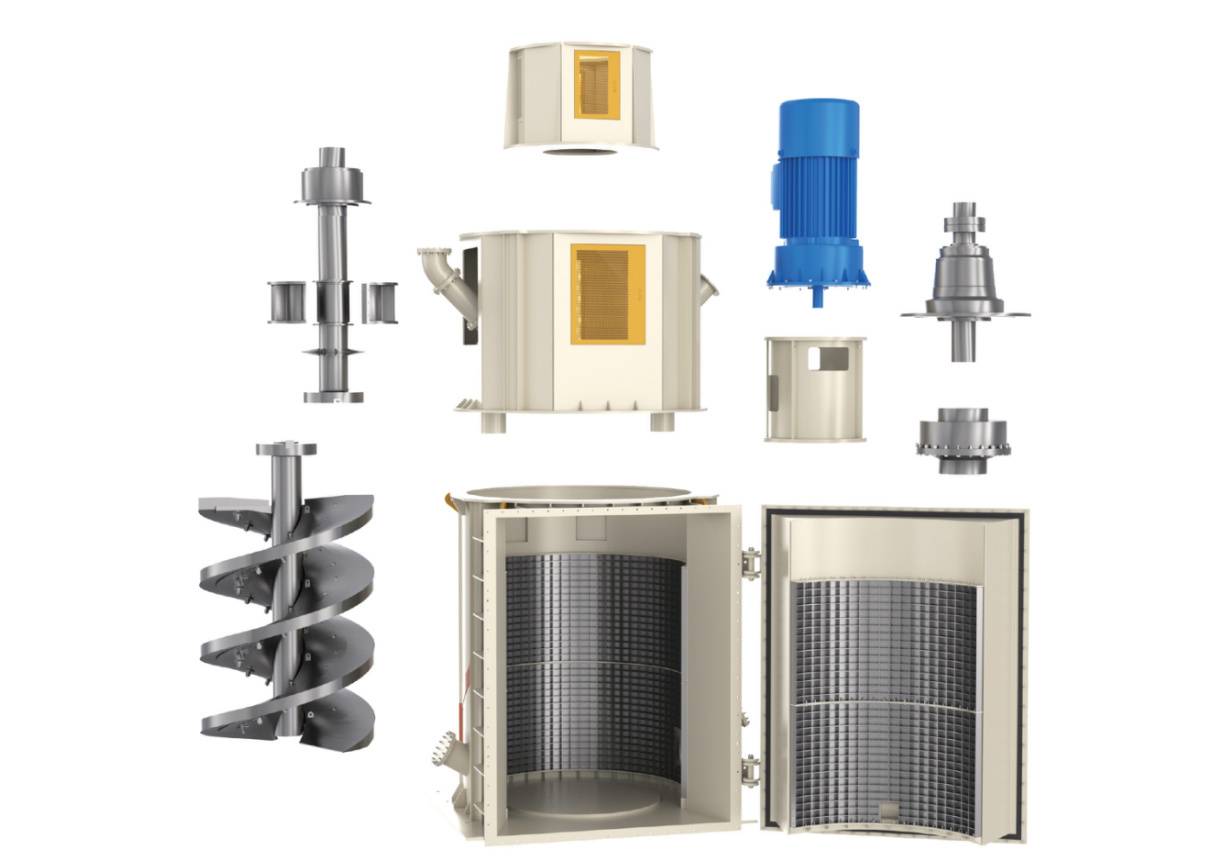

◆ Eirich type model with high energy output density;

◆ Short spiral lead, uniform radial stirring speed;

◆ Small grinding 'dead zone', few 'dead balls';

◆ Multi-metal nano-reinforced lining, long service life;

◆ Shovel shoe type bottom lining, beneficial for heavy load start-up;

◆ Modular design with disassembly tools, convenient for installation and maintenance.

Integration of military industrial six characteristics

Reliability, safety, maintainability

Testability, assurance, environmental adaptability

Special materials for reducing consumption and improving efficiency

Metal composite nano-reinforced wear-resistant lining

Significantly reduce the consumption of spare parts

Improve economic benefits of production operations

Remote intelligent control and digital maintenance

Remote intelligent control system

All-weather digital maintenance assurance

Expert service team

Efficient and professional expert service team

Providing system solutions

Modular design

Design concept of 'energy saving, consumption reduction, quality improvement, and efficiency enhancement'

Modular design based on real user needs

Balanced lamination control technology

Multi-composite material magnetic reinforcement cylinder protection technology,

Wear-resistant, anti-corrosion, noise reduction, environmentally friendly

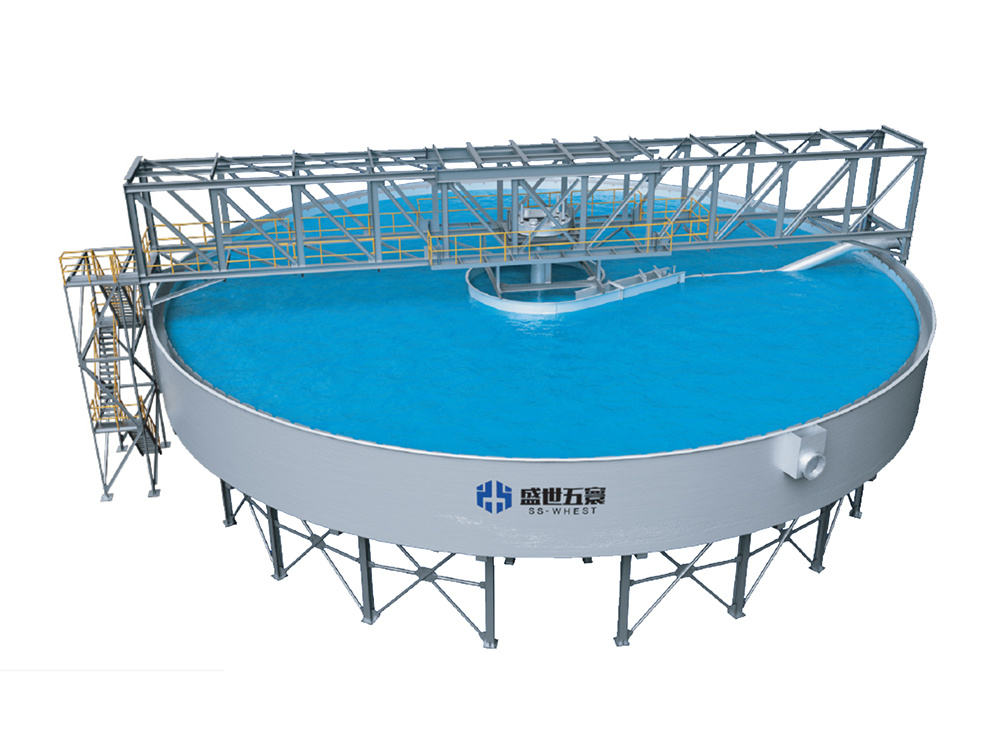

High-efficiency mineral dissociation and precise separation system platform

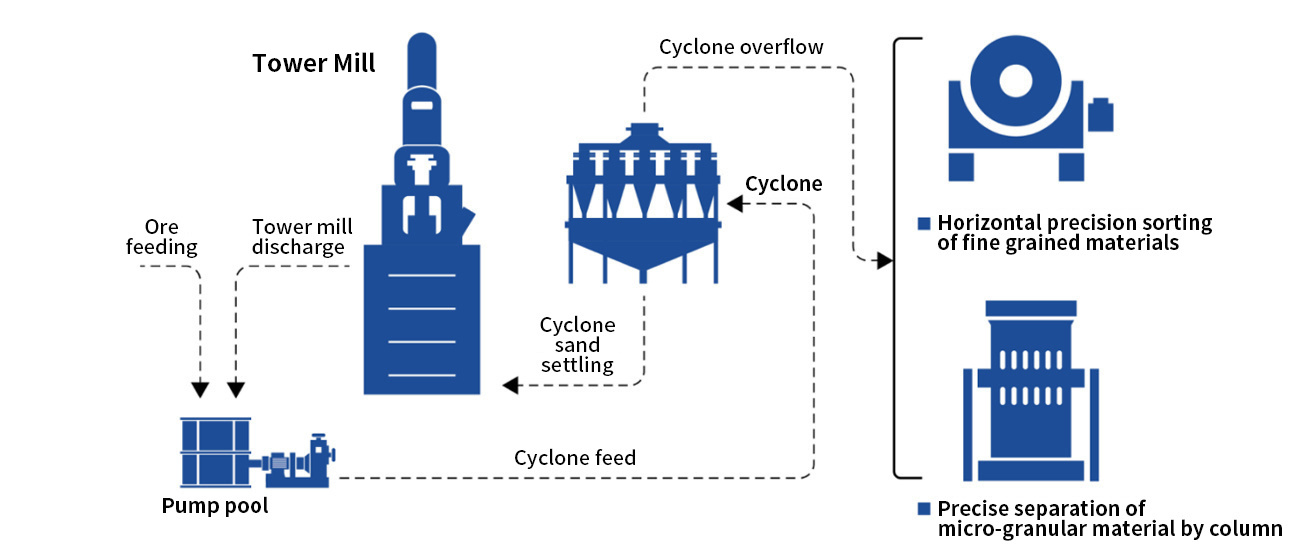

The grinding principle of the tower mill focuses on grinding with auxiliary impact, saving energy and reducing consumption during the grinding process. The grinding product has a high degree of individual dissociation and a reasonable particle size distribution, effectively avoiding 'over-grinding' and 'under-grinding'.

The 'fine grinding and precise separation system' centered on the Tower Mill effectively addresses the issue of fine particle inclusions through fluidization process enhancement technology, achieving improved concentrate grade and recovery rate.

Customized design supply of spare parts

Shengshi Wuhuan supplies spare parts for various models and provides service support. This helps customers reduce maintenance costs while ensuring optimal operational performance of the equipment and reliability of operation.

Shengshi Wuhuan strictly implements quality control at every stage of production, from raw material procurement to finished product delivery. The company is equipped with advanced testing instruments to measure various performance indicators of the products, ensuring that all products meet quality requirements.

Tower Mill Video Introduction

Tower Mill Product Specifications

| Model | Power (kw) | Processing Capacity t/h | Dimensions (L×W×H) mm |

| WTM-075 | 75 | 6~8 | 2400×2400×7500 |

| WTM-112 | 112 | 10~12 | 2400×2400×7800 |

| WTM-220 | 220 | 22~25 | 2800×2800×9350 |

| WTM-280 | 280 | 30~35 | 3000×3000×9750 |

| WTM-355 | 355 | 35~40 | 3300×3300×11500 |

| WTM-560 | 560 | 55~60 | 3800×3800×12400 |

| WTM-710 | 710 | 70~75 | 4300×4300×13200 |

| WTM-850 | 850 | 85~90 | 4300×4300×13700 |

| WTM-1000 | 1000 | 100~105 | 4300×4300×14100 |

| WTM-1120 | 1120 | 110~120 | 4650×4650×14100 |

| WTM-1300 | 1300 | 135~140 | 4650×4650×14300 |

| WTM-1500 | 1500 | 150~160 | 4950×4950×14900 |

| WTM-1850 | 1850 | 185~200 | 4950×4950×15500 |

| WTM-2250 | 2250 | 225~250 | 6000×6000×17200 |

| WTM-3300 | 3300 | 330~350 | 7200×7200×18900 |

Key words:

Related Cases

Get Quote

Related Products