High Pressure Grinding Roll

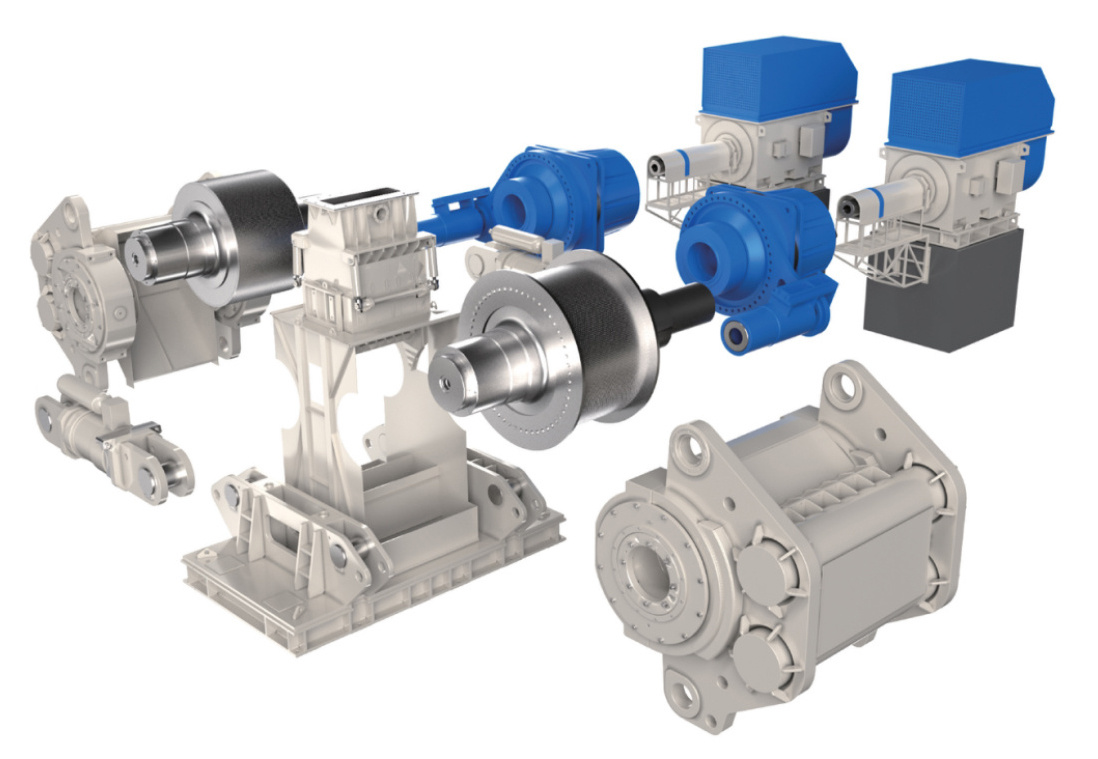

Product Description

High Pressure Grinding Roll

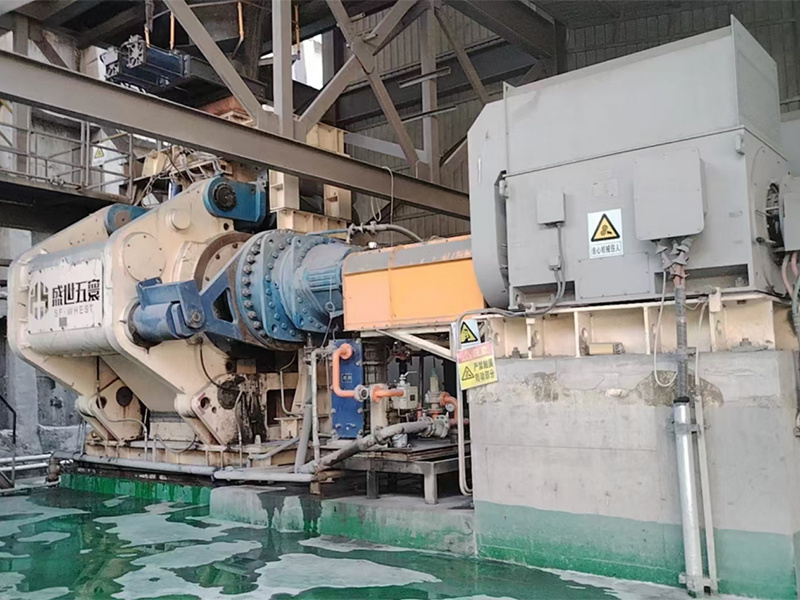

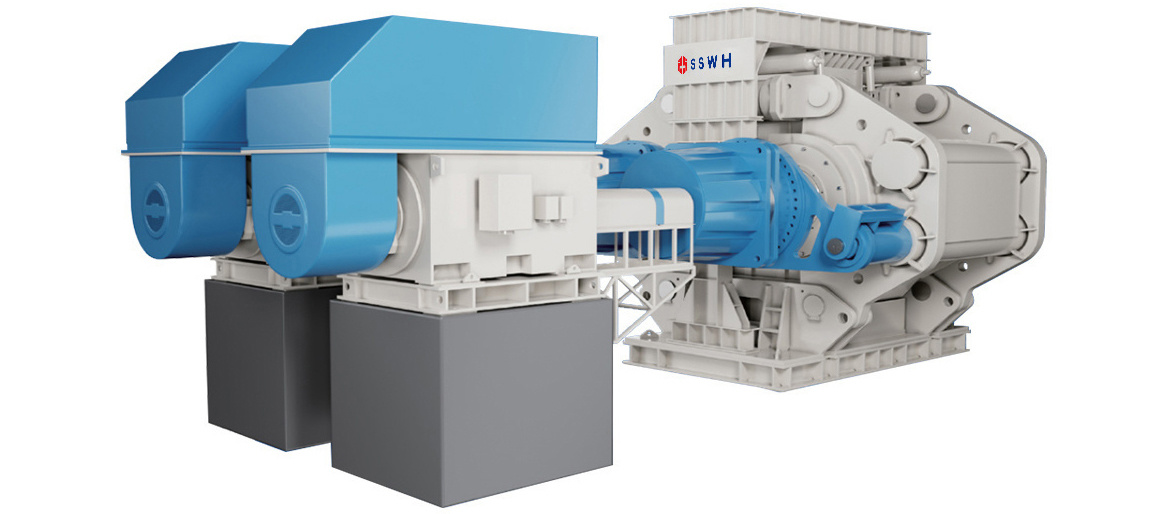

WGM High Pressure Roller Mill, adopting cutting-edge laminar crushing technology, is unique in the field of mineral processing. Its advantages are significant, high efficiency and energy saving, reduce energy consumption; large crushing ratio, uniform particle size, effectively enhance the degree of mineral dissociation, and significantly reduce the subsequent grinding energy consumption. It fully promotes the optimization of mineral processing process, improves the utilization rate of resource recovery, and leads the new development of mineral processing industry.

Technical Advantages of High Pressure Grinding Roll

◆ High efficiency, energy saving, and increased production

◆ Strong adaptability of roller surface

◆ Strong adaptability of the process

◆ Long lifespan of side plates

◆ Uniform roller surface wear

◆ Uniform product particle size

◆ Simple hydraulic control, high system reliability

◆ Convenient replacement of spare parts

◆ Internet of Things remote service

Integrating military industrial six characteristics

Reliability, safety, maintainability

Testability, assurance, environmental adaptability

Special materials to reduce consumption and improve efficiency

Multi-metal nano-reinforced wear-resistant materials

Significantly reduce the consumption of spare parts

Improve economic benefits of production operations

Remote intelligent control, digital maintenance

Remote intelligent control system

All-weather digital maintenance guarantee

Expert service team

Efficient and professional expert service team

Providing system solutions

Modular design

Design concept of "energy saving, consumption reduction, quality improvement, and efficiency enhancement"

Modular design based on real user needs

Balanced laminated control technology

Significantly reduce edge effects and lower circulating load

Laminated crushing and pre-selection technology

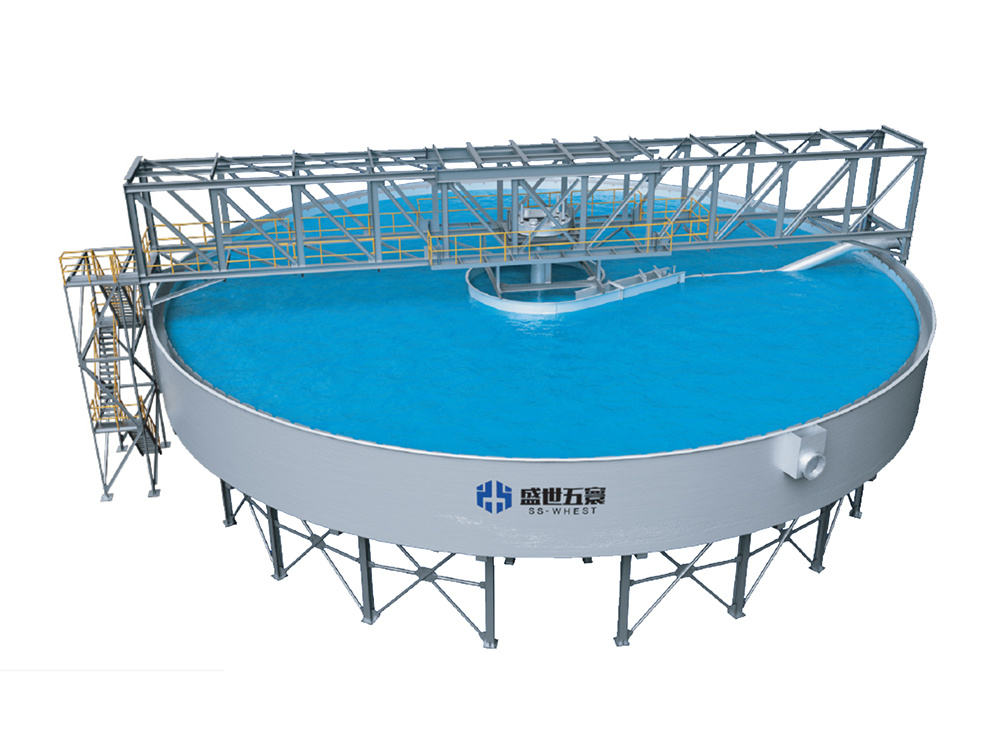

The “Laminated Crushing and Pre-sorting System”, with WGM High Pressure Roller Mill as the core, accurately reduces the amount of grinding before the material is fed into the mill by virtue of the highly efficient waste throwing technology, which effectively reduces energy consumption and realizes energy saving and consumption reduction. The system significantly improves production efficiency and reduces production costs.

Shengshi Wuhuan provides customers with the complete set of services of “Laminated Crushing and Pre-sorting System” by virtue of its profound technical background. From customization, equipment supply, installation and commissioning, after-sales maintenance, we provide one-stop solutions to meet customer needs and help mineral processing enterprises develop efficiently.

Customized design supply of spare parts

Shengshi Wuhuan supplies spare parts for various models and provides service support. It helps customers reduce maintenance costs while ensuring that equipment production reaches optimal operating performance and reliability.

Shengshi Wuhuan strictly implements quality control at every stage of production, from raw material procurement to finished product delivery. The company is equipped with advanced testing instruments to measure various performance indicators of the products, ensuring that all product quality meets the requirements.

High Pressure Grinding Roll Video Introduction

High Pressure Grinding Roll Product Specifications

| Model | Roller Specifications (mm) | Rated Throughput (t/h) | Drive Power (kw) |

| WGM-5425 | φ 540×250 | 30 | 2×45 |

| WGM-7030 | φ 700×300 | 60 | 2×75 |

| WGM-80 Series | φ 800×(400-500) | 80-100 | 2×(110-132) |

| WGM-100 Series | φ 1000×(400-600) | 100-160 | 2×(132-200) |

| WGM-120 Series | φ 1200×(400-800) | 160-400 | 2×(220-450) |

| WGM-140 Series | φ 1400×(600-900) | 360-560 | 2×(400-630) |

| WGM-150 Series | φ 1500×(800-1100) | 540-800 | 2×(630-850) |

| WGM-160 Series | φ 1600×(900-1400) | 760-1200 | 2×(800-1250) |

| WGM-170 Series | φ 1700×(1000-1400) | 1000-1400 | 2×(1120-1600) |

| WGM-200 Series | φ 2000×(800-1600) | 950-2000 | 2×(1000-2240) |

| WGM-240 Series | φ 2400×(1400-1600) | 2500-2800 | 2×(2500-3000) |

| WGM-260 Series | φ 2600×(1400-1800) | 2800-4000 | 2×(2800-4000) |

| WGM-300 Series | φ 3000×(1600-2000) | 4400-5600 | 2×(4500-5600) |

| WGM-360 Series | φ 3600×(1600-2000) | 5800-7400 | 2×(5600-7000) |

Key words:

Related Cases

Get Quote

Related Products